Cold Forging Header Analysis

December 13, 2020

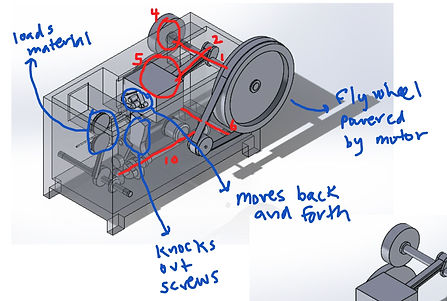

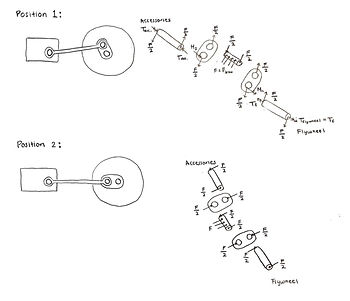

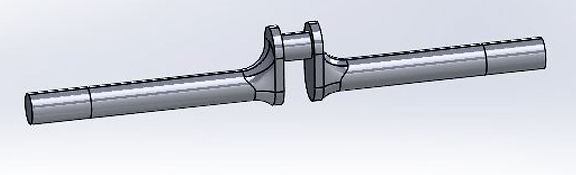

This open-ended project was completed in Engineering Design II, ME 41. We analyzed a variety of elements within a cold forging header machine, using the original patent and a SolidWorks reconstruction. We calculated feasible machine dimensions and applied forces, and modified our model accordingly. We then investigated the deformation, susceptibility to yielding, buckling, and fatigue, as well as energy, torque, and speeds of the machine. Much of this project was focused on being able to make reasonable assumptions based on initial calculations. It was a culmination of our studies in machine performance and element analysis. This project was done with a group of four. We each tackled individual pieces of the machine, and then came back to check each others' work, examine the consequences for the machine performance, and write the report all together. I focused on the fatigue and buckling calculations, as well as the CAD modifications and yielding analysis.

This video shows a version of the machine in action as it makes steel carriage bolt blanks. It is an unheated operation, and the bolt is made in two blows - a pre-heading that creates a cone shape, and the final heading that finishes the head shape of the bolt.

Final Report

Zosia Stafford, Natalie Sheehan, Jillian Stern, and Olivia Tomasetti